Improvement in oil drip pan

Corporate Data(In brief)

- Name

- TOYOTA L&F (logistics and fork-lift) CHUBU Inc.

- Business lines

- Sales, repair service & reconditioning of industrial vehicles; Sales and repair service of materials handling system

- Capital

- 40 million yen

- No. of employees

- 600

- Head Office

- 3-7-12, Shirakane, Showa-ku, Nagoya-shi

- Established

- August 1960

- Miscellaneous

Problems found before improvements

An oil drip pan is placed on the floor to catch fluid drips under the transmission or differential of the forklift at the replacement of the fluid of the forklift. Used fluid discharged from a drain plug located on the transmission/differential is caught in the pan and then put into a waste fluid storage bucket for disposal.

In a garage with which the automotive lift equipment including a vehicle-lifter is equipped, it is easy to replace the transmission fluid using such a lifter. If no such lifer is provided, the fluid must be replaced putting a low profile oil drip pan on the floor. In this case, the height of the pan must be lower than 80 mm to place on the floor under the forklift because the maximum ground clearance of under the forklift is 80 mm (for the forklifts of max. load capacity of 1 ton and 2 tons). As no oil drip pan whose height is lower than 80 mm is commercially available for now, a pair of portable jacks has been used to lift the forklift.

With this procedure, drained fluid may be splashed; waste fluid may be spilt or splashed on the floor while pouring the fluid into the bucket which might make the floor slippery (See Fig. 1).

Considering these issues, an oil drip pan has been developed that best suits for replacing the transmission fluid.

Improvements

The improved oil drip pan features:

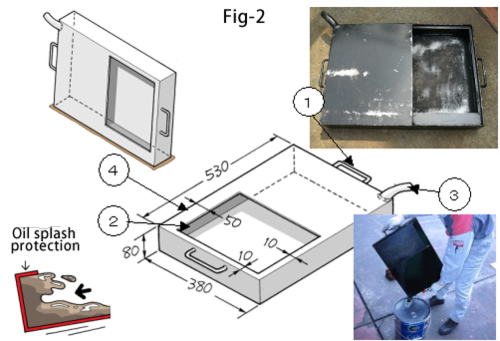

- A light, easy handling container made of 2-mm-thick iron plate having a large capacity enough for collecting full amount of drained fluid on the first time; Outer dimension: 530 x 380 x 80 mm; Capacity : 12 liters (See Fig. 2).

- A convenient carrying handle is provided to prevent fluid from spilling out while pouring the fluid into the bucket (See 1) of Fig. 2).

- A 10-mm-wide fluid splash protection is provided on top of the pan to avoid fluid spillage while tilting the pan or draining fluid as shown in Figure 2 (See 2) of Fig. 2).

- A half lid and a discharge spout are provided to prevent fluid from spilling out while pouring fluid into a waste fluid storage bucket (See 3) of Fig. 2).

- A 50-mm-wide plate is provided to prevent fluid from spilling out even when the pan is placed vertically after completing to pour the fluid into a waste fluid bucket (See 4) of Fig. 2). Vertical placement of the pan can save space for a luggage carrier of a service car, a kind of a vehicle carrying tools.

Beneficial effects

When replacing the used fluid from the transmission/differential, using the improved oil drip pan can prevent the fluid from spilling out over the floor as much as possible, which results in elimination of a hazardous oily environment.

It also improves working efficiency because it saves time for cleaning up the floor.

Another benefit is that the vertical storage of the pan can save a luggage space of a service car.