1. The Zero-accident Campaign in practice

The philosophy of the Zero-accident Campaign is to respect human life. Specific safety methods developed so that workplaces can take steps on preemptive action for safety include hazard prediction training and pointing and calling. Activities incorporating these methods in a unified manner are called hazard prediction activities.

1. Hazard prediction training (KYT)

- *KYT (K: kiken (hazard), Y: yochi (prediction), T: (training))

Using illustrations showing the workplace and work conditions, or while supervising or demonstrating work in real situations on site, discuss in small groups hazardous factors in the workplace and in work conditions (unsafe conditions and unsafe behavior that may lead to industrial accidents or accidents). Discuss, think about, and understand (or ask yourself about) the phenomena (type of accidents) that may arise from such factors, and determine the danger points and the kind of action to take, confirming these with pointing and calling, and pointing and saying out louder together. Conduct this training so that you can take steps on preemptive action for safety before you act.

The hazard prediction training based on the KYT Basic 4-Round Method and short meetings includes the following elements: Operational Direction STK Training on a supervisory level; Individual KY; KY by asking questions; One-point KY on a team level; SKYT; Individual KYT; KYT by answering a self-questioning and answering card; One-person 4R-KYT; Traffic KYT; KYT through meetings; and KYT by studying past disasters.

- *STK (S: sagyo (work), T: team, K: kiken-yochi (hazard prediction))

- *SKYT (Short-time KYT)

The KYT Basic 4-Round Method forms the foundation for all these elements. Workers openly discuss the hidden hazards depicted in the illustrations of the workplace and work conditions and solve problems by proceeding through the four rounds step by step.

- Round 1: What are the hidden hazards? (Understanding the actual situation)

- Round 2: These are the danger points. (Investigating the reality)

- Round 3: What would you do? (Establishing countermeasures)

- Round 4: These are the danger points. (Setting targets)

The KYT method increases the motivation of workers to practice in teams. It uses meetings to sharpen awareness of what constitutes danger. Workers share information on hazards and improve their problem solving capabilities by working on finding solutions in meetings. And they improve their powers of concentration by practicing pointing and calling activities in all of the important points in the work.

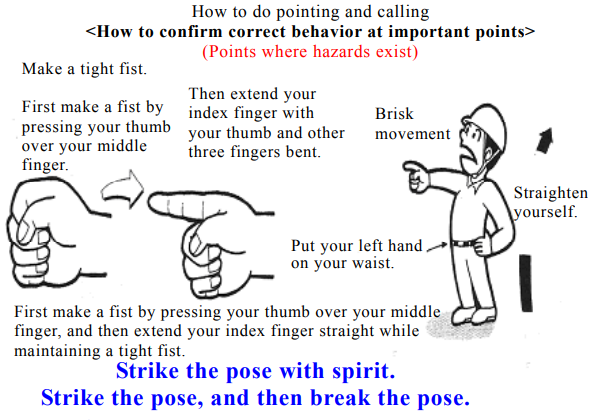

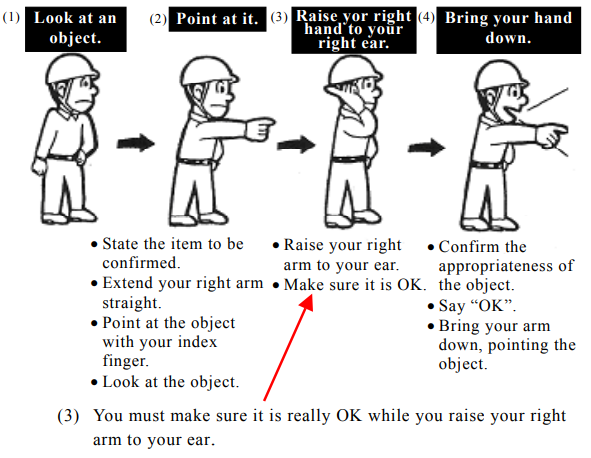

2. Pointing and calling

This activity involves pointing at target objects by stretching your arm and stating out loud, "Such and such is OK" at important points in the work in order to proceed with work safely and correctly.

Pointing and calling are methods for raising the consciousness level of workers and confirming that conditions are regular and clear, increasing the accuracy and safety of work. This method for ensuring safety is based on the philosophy of respecting human life and can be achieved only with the full participation of the workforce in practice activities across the whole of the workplace.

The results of proof testing conducted by the Railway Technical Research Institute in 1994 showed that the rate of work-related errors decreased to less than one-sixth when conducting pointing and calling as compared with doing nothing.

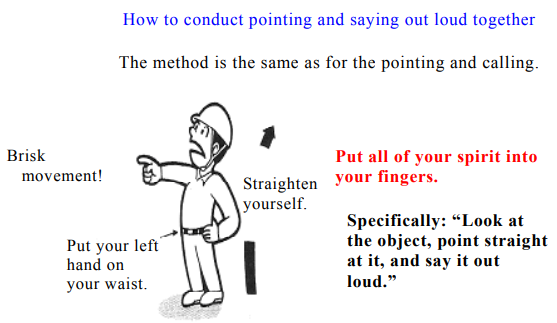

3. Pointing and saying out loud together

Pointing and calling conducted by more than two people is referred to as "pointing and saying out loud together," while "pointing and calling" is performed, in principle, by one person. The aim of this method is to join forces and to enhance a sense of oneness and community within a team by confirming the object through pointing and saying out loud together.

The "pointing and saying out loud together" method includes "touch and call" (touching, overlapping hands,forming a circle) with physical contact among all workers.

4. Other practice methods

- Health KY (hazard prediction), training for active listening, one-minute meditation, and hachidankin (traditional Chinese physical exercises that include eight types of physical movement to increase your physical strength)

- The 4-Round Method for problem solving, meetings to discuss near-miss accidents, and KYT on near-miss accidents

- Complete management of safety and health system by line managers and supervisors

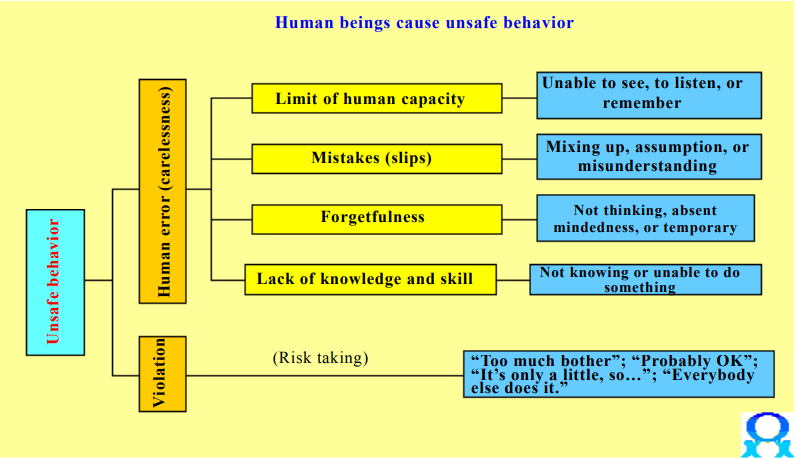

2. To prevent accidents caused by human error

The most common cause of accidents or industrial accidents is often attributed to human error such as operational error, judgmental error, and job-related error, all of which are caused by human characteristics. Most of these errors are said to be associated with psychological factors affecting human behavior. The mechanism of the occurrence of industrial accidents shows that unsafe situations, i.e., machinery failure or deficiency of work method, account for 80% of the total accidents. Work is always accompanied by issues related to human error, and unsafe behavior accounts for about 90% of all accidents, including those caused by inexperienced and unskilled workers.

Human behavioral characteristics, such as mistakes and carelessness, are called "human characteristics," and errors caused by human characteristics are called "human errors."

In order to tackle accidents caused by human error:

- Hardware (equipment, facilities, and other tools)

It is important to push ahead with safety and health measures in terms of hardware (facilities, machinery, working environment, and raw materials) for the prevention of accidents caused by human error.

- Software (human beings as well as hardware)

In addition to the above measures, it is necessary to improve the working environment including the relationship between workers and hardware as well as work from the perspective of a man-machine system.

- Humanware

Humanware incorporates the safety and health management of both hardware and software. Effective humanware hazard prediction activities incorporate countermeasures against human error and include the Zero-accident Campaign, the hazard prediction training (KYT), and pointing and calling.

3. The origins of the Zero-accident Campaign

The Japan Industrial Safety & Health Association (JISHA) was established in 1964 in order to help employers implement occupational hazard prevention programs in accordance with Industrial Accident Prevention Organization Law. That was during the era of high economic growth, over 40 years ago.

The association has provided a wide range of programs associated with industrial accident prevention since its foundation. For example, the Zero-accident Total Participation Campaign (Zero-accident Campaign) was started with the support of the former Ministry of Labour in 1973, ten years after the foundation. This campaign originated from the idea to "Zero in on Safety" (Focus on Safety) implemented by the National Safety Council (NSC) in the US. It was also based on the concept of carrying out activities for quality control (QC) method.

4. What is the Zero-accident Total Participation Campaign?

This campaign aims to create a bright and cheerful climate in the workplace based on the philosophy of respecting all human life as irreplaceable. From the perspective of the workers and with respect for each and every human life, the campaign insists on zero tolerance of industrial accidents, with the ultimate goal of zero disasters and zero diseases. The campaign aims to take steps on preemptive action for safety and health issues and to solve dangers and problems in the workplace with the participation of all workers.

5. The basis of the Zero-accident Campaign

Each and every individual human being is irreplaceable. Nobody deserves to get injured or die. The basis of the Zero-accident Campaign is for all workers to take steps on preemptive action for safety and health issues so that nobody on the worksite gets injured. The Zero-accident Campaign aims for zero accidents in the workplace.

The Zero-accident Campaign is based on the philosophy of respect for human life, but it is not merely a psychological campaign. It incorporates techniques for specifically implementing and realizing its philosophy and practical methods for putting those techniques into practice in the workplace. The goals of the Zero-accident Campaign can be achieved in a practical setting only by combining the philosophy (spirit) of the campaign with effective techniques. The Zero-accident Campaign should be implemented on the basis of its three indispensable elements: philosophy, technique, and practice, and it should lack none of these elements.

6. The three basic principles of the Zero-accident Campaign

The Zero-accident Campaign builds on the three principles of zero accidents, preemptive action, and participation. These are called the three basic principles.

- The principle of zero accidents

"Zero accidents" means to achieve an accident free workplace (not only no fatal accidents or accidents causing absent from work, but also no accidents, including industrial accidents, occupational illness, and traffic labor accidents) by detecting, understanding, and solving all hazards (problems) in everybody's daily life as well as potential hazards existing in workplaces and work.

- The principle of preemptive action

"Preemptive action" means to prevent all accidents and industrial accidents by detecting, understanding, and solving all hazards (problems) in everybody's daily life as well as potential hazards existing in workplaces and work in order to create a brighter and more vigorous workplace with zero accidents and zero diseases as an ultimate goal.

- The principle of participation

"Participation" means to make a concerted effort by managers, supervisors, staff, and workers to detect, understand, and solve potential hazards (problems) existing in workplaces and work. It requires the voluntary effort and commitment of all those involved in actions for problem-solving.

7. The three important pillars of the Zero-accident Campaign

Implementation of the Zero-accident Campaign requires three important pillars: the positive attitude of the top management; the complete management of the safety and health system by line managers and supervisors; and the promotion of voluntary activities in the workplace. The Zero-accident Campaign depends on the mutual relationships and assistance of these three pillars.

- (1) The positive attitude of the top management

The starting point of safety and health activity is a tough attitude held by top management towards zero accidents and zero diseases. The campaign starts with a determined commitment by the senior management to respect every single worker and ensure no injuries. A positive attitude change at the top alters everything. Top managers must take the initiative in changing their way of thinking regarding zero accidents.

- (2) The complete management of the safety and health system by line managers and supervisors

In order to promote safety and health in the workplace, it is essential for line managers and supervisors to lead by example by integrating safety and health activities into day-to-day work, making safety and health part of the line management. Complete management of the safety and health system by line managers and supervisors is the second pillar of the Zero-accident Campaign.

- (3) The activation of voluntary activities in the workplace

Human error plays a part in most industrial accidents, and each and every worker needs to be fully aware that responsibility cannot be shifted to others. Workers must engage in small group activities for zero accidents with the awareness that their existence is irreplaceable for their families and dependents and safety and health is their own and their co-workers' own problem.

Safety in the workplace will not be ensured unless every worker takes part in the practical activities with the positive attitude of "I will not get injured" and "My co-workers will never get injured."

8. The integrated operation of occupational safety and health management and the Zero-accident Campaign

Having an industrial safety and health management system is an effective way to embody the three pillars of the Zero-accident Campaign: the positive attitude of the top management; the complete management of the safety and health system by line managers and supervisors; and the promotion of voluntary activities in the workplace. The system should underline the commitment of top management to the safety and health policy. It should enable the development of a safety and health plan for achieving the safety and health goals. It should make clear the roles, responsibilities, and authorities of each level of line management. It should involve the PDCA (plan・do・check・act) cycle for each stage. And it should identify and eliminate or reduce all dangers and harmful factors.

The system is operated by human beings, so, to make it function properly, it requires the motivation and enthusiasm of all of the people involved in it, namely the top management, the line managers, and the workers. The industrial safety and health management system takes this motivation and enthusiasm and develops workplace climates and human resources in an integrated manner in line with the Zero-accident Campaign, producing further effects that will contribute to the prevention of industrial accidents.

Effect of Zero-accident Total Participation Campaign

Y Company has introduced Zero-accident Total Participation Campaign in their whole workplace. Since introducing Zero-accident campaign, they first focused on OSH education and revitalized KY activities at each workplace. As the pointing and calling became established in daily work, efforts for employees' safety and health became very aggressive.Thanks to the introduction of Zero accident campaign, occupational accidents have also decreased substantially. It became about one third before introduction 5 years after introduction and it was about 1/10 after 17 years. The accidents frequency rate (per 1 million working hours) is maintained at a low level of 0.16. (Case of Y Company (In Japanese Language))

History of Zero-accident Total Participation Campaign

Zero-accident Total Participation Campaign has been advocated by JISHA (Japan Industrial Safety and Health Association) and has been utilized by Japanese industrial sectors since 1973.

(Reference) Concept of Zero-accident Total Participation Campaign in Multilanguage